Select Language

Select Language

Crafting Excellence Through Comprehensive Advantages

I.Exceptional Customization Capabilities Shaping Core Competitiveness

In the fields of material formulation and mold R&D and production, we possess unparalleled customization capabilities. Leveraging our advanced material database—housing vast amounts of material property information—our intelligent analysis system precisely identifies correlations within the data. Combined with our senior technical team of industry elites, the powerful synergy of these three elements opens the door to a seamless, end-to-end customization journey for our clients.

All our resources are dedicated to meeting clients’ highest expectations for product performance or addressing the stringent demands of specific application scenarios. We excel at starting with meticulous needs analysis, delving into critical factors such as the physical stresses and chemical environments the product must endure. We then refine material formulations, carefully optimizing raw material ratios and tailoring the microstructure of materials. Concurrently, we advance mold design, creating perfectly adapted mold “shells” based on product geometry and molding processes. Small-batch trial production serves as a rehearsal for new products, enabling early issue detection and solution optimization. Rigorous performance testing monitors every manufacturing step to ensure all product indicators meet standards. Every phase of this process is executed with precision, achieving 100% alignment with the required product performance.

II.Lightning-Fast Response: Ensuring Efficient Delivery

1. Instant Project Initiation

Upon receiving client requirements, our technical team develops a design proposal integrating professional expertise and preliminary concepts within 24 hours, gaining a head start for rapid project advancement.

2. Ultra-Short Routine R&D Cycle

We can achieve innovation from scratch and complete rapid iterations in as few as 2 to 3 working days, addressing clients’ urgent needs for new product launches.

3. Seamless Emergency Mass Production

Once a formulation is validated, our production lines immediately ramp up to support trial production within 24 hours. Even for emergency orders, we respond with agility, ensuring no delays in meeting critical demands and helping clients seize market opportunities through speed.

III.Rigorous Problem-Solving: Fortifying Quality Assurance

1. Full-Process Risk “Firewall”

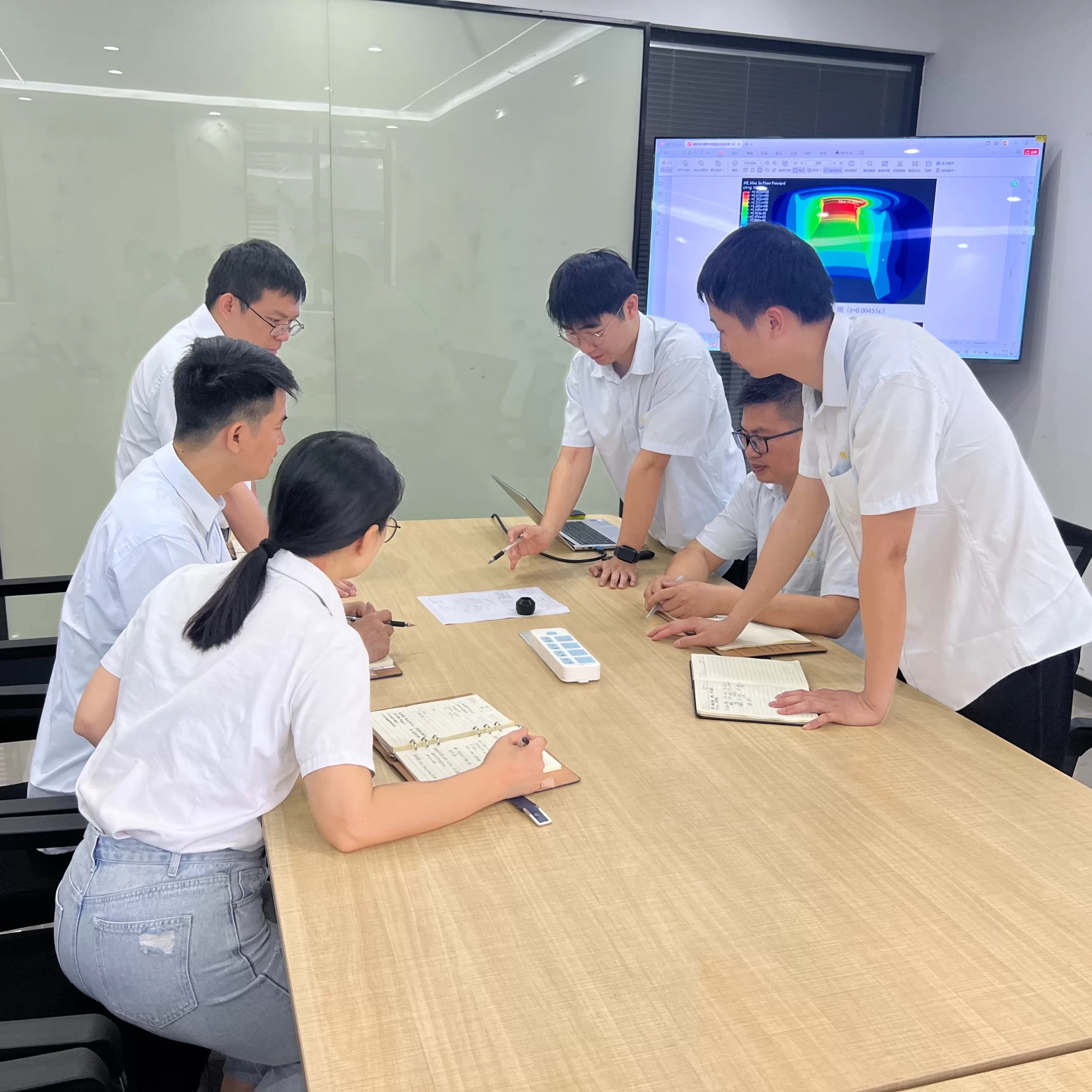

Front-End Prevention in Formulation Design:At the critical stage of formulation design, we employ simulation technology as a “safety net” for product performance. By pre-simulating product behavior under various operating conditions and conducting pre-tests, we accurately identify potential performance deviations and nip risks in the bud.

Real-Time Production Monitoring:During production, our fully automated batching system not only measures raw materials with precision but also monitors mixing process parameters in real time. Every batch of material blending is strictly controlled to ensure batch consistency and stable product quality.

2. Rapid Problem Response “Blitz”

Swift Technical Issue Resolution:If technical challenges or delivery obstacles arise during project execution, our dedicated project engineering team convenes immediately and provides specific optimization plans within 2 hours, ensuring uninterrupted progress.

Root-Cause Traceability for Quality Issues:We adhere to a no evasion principle for quality problems, completing root-cause analysis and implementing corrective actions within 48 hours to resolve issues at their source and eliminate client concerns.

3. Transparent Communication “Bridge”

Synchronized Project Updates:Embracing open communication, we regularly inform clients of project development progress, keeping them fully updated throughout the process. At key milestones, we invite clients to participate in validation, transforming them from mere “observers” into active “participants.”

End-to-End Data Traceability:We retain records of all data—every adjustment in formulation design and every detail in production logs—enabling easy traceability of formulations and production records. This ensures project controllability and allows clients to entrust us with their projects with confidence.

IV.Reliable Service Commitments

1. Backed by International Standards Certification

We strictly implement the ISO 9001 quality management system, ensuring every project phase adheres to the highest standards and requirements, providing clients with reliable quality assurance.

2. Empowered By National-Level Testing

Equipped with national-level laboratory testing equipment, we deliver precise and authoritative product testing. Whether for sample testing of customized products or sampling/full inspection of mass-produced items, we provide professional, objective test reports to validate product quality.